Your "one stop shop" for product design.

|

|

SAGE designs products of all types, from concept right through to manufacture.

Our services include concept design, industrial design, mechanical design, and a

host of related engineering disciplines necessary for product success.

We use our many Asian contacts and suppliers to provide low-cost prototyping,

tooling and manufacturing.

Call us anytime for a chat as to how we can work together to create a world-beating product.

Our services include concept design, industrial design, mechanical design, and a

host of related engineering disciplines necessary for product success.

We use our many Asian contacts and suppliers to provide low-cost prototyping,

tooling and manufacturing.

Call us anytime for a chat as to how we can work together to create a world-beating product.

Total Product design - from concept to production

SAGE can take you from concept right through to production. We can write the product specification, do the industrial design, the detailed mechanical design, the 3D modeling of each component, arrange prototyping, write the test plan, test the product, liaise with Asian toolmakers to get it tooled, create the manufacturing package and get it into production and out the door to your markets We can also help with “engineering” functions such as designing heat-sink or optical components, calculating air flow and heat rise, design for EMC compatibility, connector selection or design, wiring harness design, specification sourcing and testing of key third party components such as pumps and motors, design of control algorithms, user interface design, specifying and designing in specific points of IP for sustained competitive advantage, consider industry specific abuse, consider regulatory compliance issues, define test criteria and procedures, write work instructions, design assembly jigs – to name a few. |

A good example of SAGE total design - hi-tech electronics integrated with bomb-proof mechanical packaging. Standard sheet metal parts, precision tooled metal parts and plastic injection moldings. Distribution of hundreds of amps combined with micro-power electronics. Connector selection. Busbar design. Thermal management. Design for manufacture. Asian sourcing.

|

Additional "added value" activities SAGE can help with...

|

|

Design for all manufacturing processes.

|

Example of injection molding

tools manufactured in Asia |

Experience, experience

|

An Emergency Wrist Alarm

designed for a Sydney customer |

SAGE provides design

|

SAGE provides design services

throughout Australasia. |

From the simplest bracket

|

Brackets, widgets and more brackets. No glossy plastic, fancy

curves or design awards for these parts, but this is exactly what this Sydney customer needed. Designed in New Zealand by SAGE, manufactured in China, shipped to the customer in Sydney. |

Design of hi-tech electronic

|

An example of the low-cost integration of many electronic components using an injection molded cover clipped onto a die-cast case half/heatsink. Note the smaller details such as custom designed light-pipes and FET clamps which make this design possible.

|

Medical device design and Healthcare Product design. |

|

With over 10 years experience in the design of rehab, mobility and healthcare products for the international market we are well versed in the procedural, regulatory and functional requirements peculiar to the medical device sector. We understand the different aesthetic and UI preferences that prevail in particular parts of the World, the worlds of regulatory bodies such as FDA and TUV, the needs of distributors, dealers, health professionals and end-users, the absolute need for safety and reliability, the special needs of those with limited physical and cognitive skills and the techniques and interfaces required to overcome them. |

Design of connectors

|

A few examples of custom electrical contacts designed by SAGE.

|

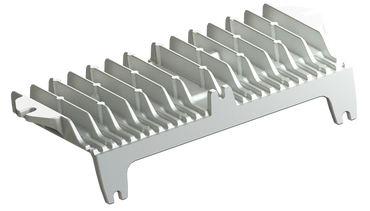

Heat-sink design and

|

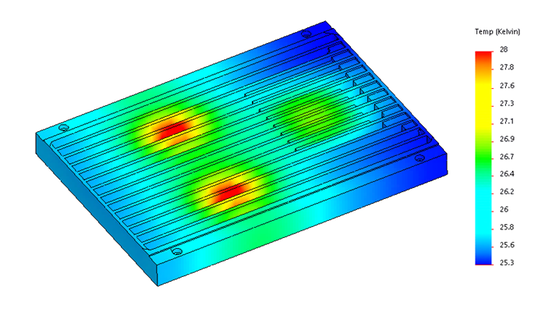

Computer simulation of thermal issues can

save you a lot of money, a power of heartache, and get your product to market a lot faster. An example of a "heatsink" that is much

more than a heatsink - when combined with an injection molded plastic cover it forms the entire product enclosure. |

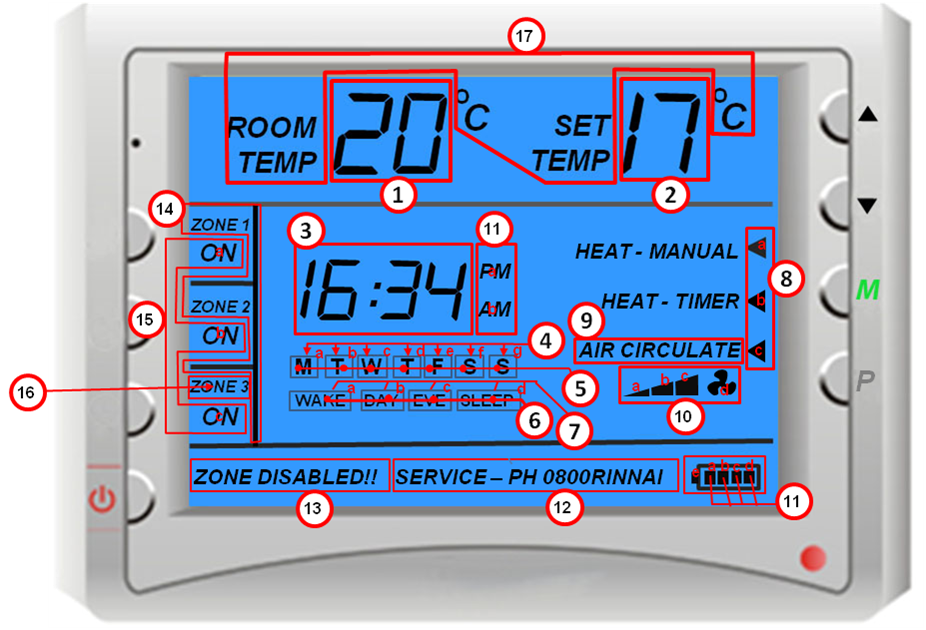

User Interface design

|

SAGE User interface design for a thermostat

|

|

Look around and you will find any number of examples of physical user interfaces that you are lucky to be able to find let alone use.

You will find switches and buttons that require motor skills and targeting beyond the capabilities of many of the intended users, faucets that can only be operated by the left hand, cars whose dashboards look like they were created in a drug induced haze, car gear shifts with so little movement the driver has to look at the gear shift while they change gear, car door handles in the wrong place for best mechanical advantage, refrigerator doors whose handles can only be used by midgets, Graphical User Interfaces (GUI) covered with arcane icons that are too small to target, hidden roll-over options, meaningless and inconsistent labels, poor contrast lettering...regrettably the list goes on and on. Here are some UI areas SAGE can help with... |

|

Design Troubleshooting

|

This keypad is "sweating" causing

unreliability in its contacts. |

Prototypes and

|

An example of the level of quality of prototyping that can

be achieved - it can be very difficult to distinguish them from the real thing. Prototypes at a number of stages throughout the project are an absolute essential. |

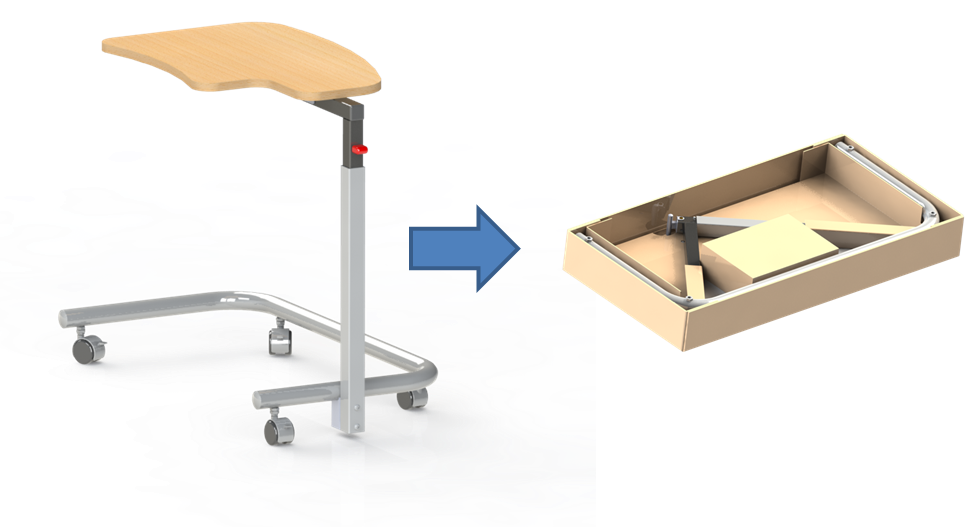

Product PackagingPackaging design is a key part of any design project which because it does not fall neatly under the jurisdiction of common engineering disciplines often slips under the radar and becomes a crisis job at the end of the project. A product's shipping and packaging requirements need to be considered up front and assigned specialist attention so that the packaging is no less a product than the product itself. SAGE has wide experience in the design of packaging for both bulk distribution and retail display purposes.

|

An example both of design of a product specifically to make it

possible to be economically shipped from the manufacturer in China to the customer in Australia, and of the packaging design itself. |

|

Example of a custom designed tray to enable PCBs

to be economically shipped from the PCB house in China to the customer in America where they would be assembled into the final product. |

Showing the level of detailed design required for more

elaborate packaging. This packaging is specially designed to be used to package a number of different shaped products, allowing a reduction in packaging inventory. |

Manufacturing and

|

A production jig to hold plastic moldings

to facilitate potting of electronics |